How to Ensure Clean, Uninterrupted and Sufficient Power in Your Business Facility

If you’re a business owner, then you’ve already witnessed firsthand just how much more challenging today’s business climate is than it’s ever been. For small and medium-sized businesses, however – and manufacturers in particular – the urgency for staying competitive has never been greater.

For many Australian manufacturers, identifying which of their production activities can cost-effectively be automated has become an integral part of the overall business plan. That’s why robotics and other forms of automated and semi-automated processes are seeing ever-expanding use for repetitive, delicate, and increasingly more intricate tasks. And not surprisingly, the progress that’s also been made in quality and consistency has been astonishing.

Business owners understand that industrial automation isn’t just about pressing a button and walking away, though. They also understand that complex electronic systems need clean, uninterrupted power, and seamless data and signal integrity to achieve flawless results.

The biggest obstacle to top-notch performance has traditionally been the integrity of the cable and wire assemblies being used. Fortunately though, the engineering of robotic cable assemblies has evolved to meet the needs of these sophisticated systems; and the picture for cost-effective automation has never looked clearer than it does right now.

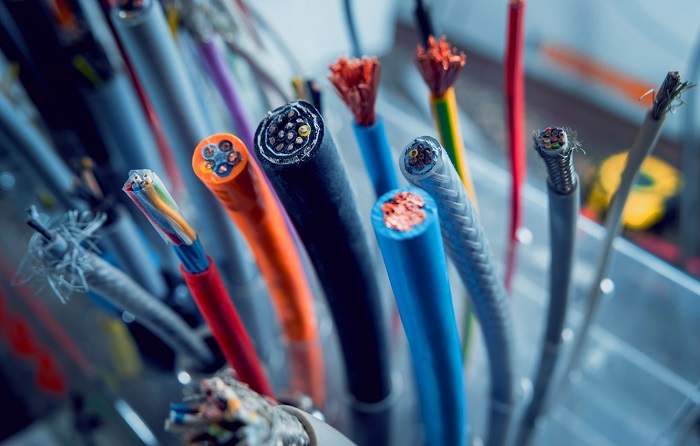

Cable Quality

Modern automation doesn’t just depend on cabling that’s sturdy: it has to be smart too. And, it has to do both 100% of the time. That’s why for industries where automated cycle rates consistently need to be at their highest, cable assemblies from Igus Australia are synonymous with meeting the power and data demands that businesses want from their robotic processes. Their highly flexible control cables and cable chains are designed specifically to resist the loads and rigours of repetitive motion applications where frequent bending, winding and unwinding, and stretching can end up in extensive maintenance issues and prolonged downtimes, as well as lost productivity.

Igus understands that automation isn’t just about manufacturing. It’s all about processes. And that’s why you can rest assured that their flexible power cable and control cable assemblies are able to deliver cable quality like no other.

Unharnessed Cables

What many business owners realize after they’ve automated a process is that not all cables and wires are built to withstand the mechanical stresses of large cycle numbers, the twisting, or the rapid accelerations and decelerations that are an inherent part of automated systems. Along with the full scale of motion, these cables also need to have fail-safe reliability to do the job. That, however, is precisely what you can expect from unharnessed cables. Unharnessed flexible cables are available for light, medium, and heavy-duty applications, and for all types of ambient environments. From pharmaceutical cleanrooms to mining operations, a full range of standard unharnessed control and power cable solutions are available, along with a broad array of specialized cables, such as:

- Data cables;

- Can bus cables;

- Robot cables;

- Servo cables; and,

- Pendant cables.

And complementing their varying range of applications, flexibility, and resistance to interference, unharnessed cables also possess the necessary core of high-risk protections that are mandatory for safe working environments, including:

- Halogen- and silicone-free composition;

- Fire resistance;

- Hydrolysis and microbe resistance;

- Oil and coolant resistance; and,

- UV resistance.

In short, when business owners are ready to buy power cables for their automated systems, these are the cables they need to insist upon.

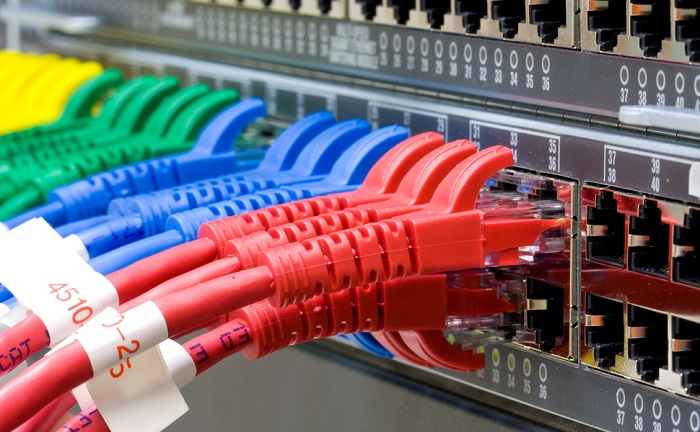

Energy Chains

An energy chain, or drag chain, is the segmented, flexible cable conduit that’s used to guide and protect the cables, wires, and hoses used by the automated systems; and they’re installed in everything from vending machines to the world’s largest crawler cranes. Their lightweight, modular construction also provides maximum shielding from electrostatic discharge (ESD), as well as exposure to extreme temperatures, dust, chemicals, or other hazards that could lead to electrical cable failure.

Depending on the application, energy chain solutions can be designed to follow either linear or rotary cable troughs up to 1,2km long, as well as along vertical planes, with the added benefits of:

- Low weight;

- Low maintenance requirements; and,

- Long service spans.

Energy chain solutions cover the full scope of automation options by being infinitely scalable and easily configurable automation assets whose real-time performance can even be monitored by energy chain sensors. For production managers and resource planners whose job is to consistently deliver the highest quality finished goods possible, the advantages of automation couldn’t be more evident.

Taking the Strain Out

The long life and flexibility of unharnessed cables, and the strong attributes of energy chains make a solid combination, but it takes securing the two together with the correct strain relief devices for it to be a successful one. Energy chains use a variety of perfectly integrated elements like clamps, separators, and honeycomb elements to provide strength and stability for electrical cables without compromising their flexibility. It’s the ease and simplified installation of strain relief devices that enable the way cables and wires are fitted and retrofitted to contribute directly to:

- Greater cable resistance to higher machine accelerations;

- Greater tensile holding strength; and,

- Greater cable insertion and stacking densities.

With strain relief, entire mechanical components and their associated cable runs can be swapped out quickly without significant downtimes or commitments in man-hours. It’s all-in-one convenience and cost-efficiency, and that’s what businesses expect to achieve by going to automated solutions.

The Final Word

At the end of the day, so much of what’s achievable with robotics and other automated and semi-automated processes isn’t altogether about the machines. If the cables providing the power and control data are unable to perform reliably or sufficiently, a business can quickly find itself facing a greater challenge than if it hadn’t opted to automate at all.

When it comes to the integrity of power and control data cabling, Igus Australia has the products and solutions to give businesses the clear competitive advantage they expect to gain from automation.

If you’re a business owner, and you’re either considering automating more of your processes, or contemplating ways to make your existing ones more efficient, then now’s also the time to start thinking about how much of a difference changing your cabling could make.