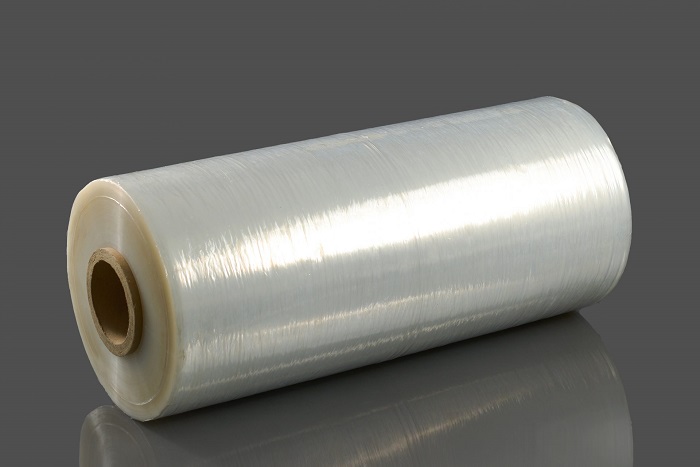

Exploring the Different Types of Stretch Films

The main purpose of stretch films is to hold boxes and products together on a pallet for transportation and help reduce product loss, discourage load tampering, prepare products for placement on pallet trucks and shipment, and reduce worker injury.

The elastic recovery is tightly bound around the products, keeping them in place without leaving a sticky residue behind. The two most commonly used extrusion processes are cast and blown. Extrusion is the manufacturing of stretch film. Stretch films come in many different types and each one of them has qualities that are suitable in addressing the specific needs of your stretch wrapping operation.

Contents

Cast Stretch Wrap

Cast stretch wrap is manufactured using a cast extrusion process and it provides a stretch film that requires less force to stretch, has increased tear resistance, unwinds quietly and offers a superior cling. There are machine grade and hand grade stretch films, so you can choose what’s most suitable for your packaging operation. You can find a spiral film with excellent quality and high strengths, versatile and suitable for various types of commercial and industrial applications.

The spiral film is a widely used method for pallet packaging and securing pallet loads for shipping. Low-density stretch film is pre-stretched 60 to 400 percent before being wrapped around the pallet load. Then, the spiral film is applied to the pallet load and depending on the volume of pallets being packed, it can be integrated with a manual turntable packing model. As the name suggests, the operator cuts and attaches the film to the pallet load by hand, or with fully automatic rotary arm models with a top sheet dispenser, where automatic film roll changes and speeds up to approximately 100 pallet loads per hour.

In the case of turntable wrapping machines, the load is placed on a turntable that rotates in front of the roll of film, but when it comes to rotating arm wrapping machines, the load is stationary and the arms rotate around the pallet. In the case of ring stretch wrapping machines, the carriages move around the static load. With pallet stretch wrapping machines, you can set many different parameters such as the number of film layers to deposit on your pallets, the film deposit force, roping and more. Also, you can find several accessories available to help you make the entire process much easier.

It’s a great choice for larger and longer products and packs, providing a cost-efficient way of wrapping large items of commercial and industrial equipment, as well as furniture. Supplied on a roll, the film can be spiral-wrapped around and along an item to secure it and protect it, regardless of its size, length or shape. The spiral wrap film can be applied to the pallet load in a variety of patterns depending on the load stability and protection required.

Blown Stretch Wrap

Blown stretch film is manufactured using the blown extrusion process. It’s robust and resilient stretch wrap type, with significant load holding power. Blown stretch wrap offers high stretch capacity and allows product loads to stay secured for a long time, but it has poor clarity and is noisy when unwound from rolls. It’s often used for securing loads with sharp edges, irregular loads, bagged or boxed products and more.

Benefits of Stretch Films

Prevent Damage of Products

Stretch wrapping is probably the most popular pallet wrapping method lately. It prevents products in the process of moving, shipping and/or storing, so sudden movement, improper handling or environmental factors can’t affect your products. Not only does a stretch wrap keep products and boxes together on a pallet, but also it keeps them free of dust, moisture and dirt.

Improve the Packaging Process

Stretch wrapping uses less energy to operate compared to other unitising methods, like shrink wrap systems, for instance. It’s very efficient because it improves the flow of the packaging process, increases workers’ productivity and provides better inventory control. Moreover, many stretch films are recyclable and available in a wide variety of standard and special attribute blends to address different stretch wrap packaging applications.

Durability

Stretch film wraps are very durable and difficult to break, so they can protect your products from the wear and tear associated with movement, storage and shipping.

Safety and Hygiene

Stretch wrap films protect your goods from contamination with germs and malodour from the manufacture, through distribution to storage and display.

Cost-Effectiveness

Stretch wrap films are a cost-effective packaging solution for any business out there. They save both the cost to protect products properly and get products to consumers in the safest way possible. However, it’s good to know that in the packaging world, stretch film and shrink film are terms that are often used interchangeably, but the difference between the two is very big. They sound similar, and packaging supply companies usually sell them both, so it can become confusing to differentiate one from the other. Stretch films and shrink films have different uses. While stretch film wraps and protects industrial pallets, shrink film is used to wrap consumer goods for easy packaging and shelving, like water bottles, soda cans, pharmaceutical goods, sporting goods or else. One can’t be replaced with the other and that’s why it’s important to make sure you choose the right one for your needs.