Why Is a Chocolate Making Machine so Vital for Every Supplier in the Industry?

There is a large number of specialized equipment for every industry and almost every kind of job. This sort of equipment is designed to be perfect for a specific task, but virtually useless for others. This means that while there are certain tools and pieces of machinery that are better when used as all-purpose helping devices, others have a singular use, yet are vital to the work that is being done. A good example of this is the chocolate making machine.

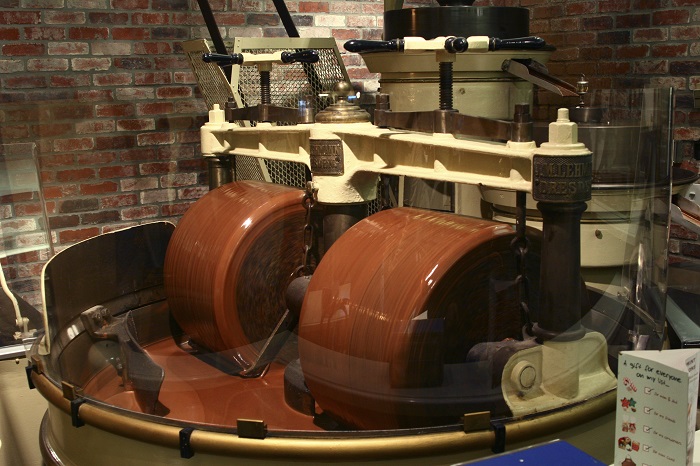

The purpose of the chocolate making machine is, as the name suggests, to make chocolate. They are usually very large and complex because of the many components that need to work together

for everything to be done properly. Even though the many aspects of the machine mean that every part of the process can easily be completely automated, some think that the risk of the entire operation shutting down because of a malfunction of just one of the parts is unacceptable. This, as well as the initial buying costs are the main reasons why a lot of suppliers prefer to do it the old-fashioned, manual way.

But, the only important parts of the process that can really still mostly remain manual are the preparation of the ingredients by way of grinding and separating, the maintenance of the equipment and the transport and distribution. And while there are also parts of the chocolate making itself that can be done by hand, they would take significantly more time, and be completed with significantly less efficiency. However, if suppliers decide that they do in fact need a proper chocolate making machine, then there really aren’t many other things that they need other than the machine itself and all of its components.

In the machines, the process starts out in the de-moulding and preheating machine into which the chocolate stock and ingredients are placed and dropped down onto a conveyor belt in the shape of a formless cream-like substance. Later on, the conveyor belt that connects all of the components takes them through the one-shot depositor that provides the filling of choice (nuts, caramel, raisins etc.), and into the vibration machine than gives them their form, as well as the pre-cooling tunnel that solidifies that form a bit. Finally they are taken through another heater before going into the mould-closing machine, and end up in the final cooling tunnel ready for packaging and distribution.

If the above mentioned process is something that suppliers think will be better if it was done by hand for whatever reason, then it is true that it can be. But from a financial aspect it makes no sense since the machine will cover its initial cost in a very short amount of time. In addition, the supplier is more likely to lose more money because the workers will only be able to provide the same amount of chocolate as the machine if they are given at least twice the amount of time.