The Benefits of Flap Discs and How to Buy the Right One

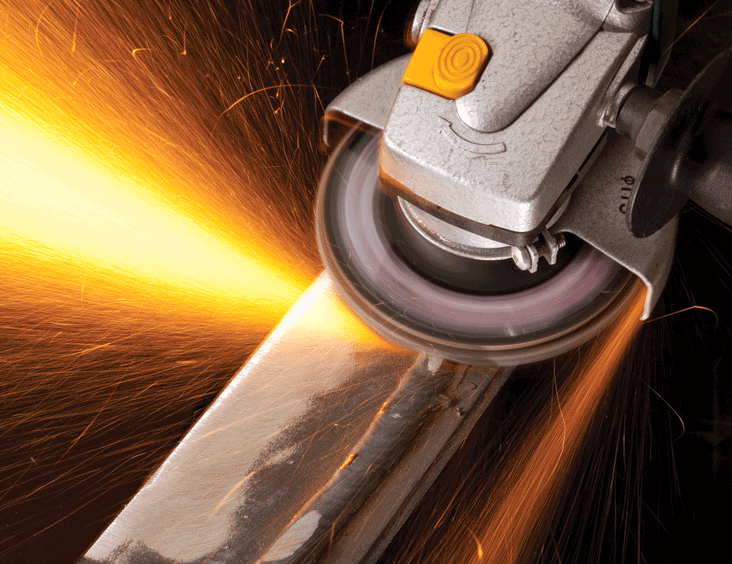

Flap discs are a commonly used tool to blend, finish, and remove excess materials in a quick matter. They’re designed for angle grinding applications ranging from smooth finishing, surface blending and heavy stock removing. The fact that flap discs are so versatile, lightweight, easy to maneuver and require less change over time makes them ideal for performing abrasion tasks. Many users prefer them over grinding wheels due to their lower noise and vibration levels.

Over the last couple of years, flap discs have become one of the most commonly sought after abrasives in the metal fabrication industry. This is mainly due to the fact that they offer high-performance at comparatively lower costs. If you’re looking for flap discs, there are a couple of factors you need to consider in order to make the best choice possible.

First and foremost, you need to pick between conical and flat flap discs. Conical flap discs are mainly used for removing excess material, quickly. They can be used for contoured and edge-working applications and aggressive stock removal, due to the fact that they provide a greater surface area contact. Flat flap discs, on the other hand, are for quality finishing and blending.

But regardless of which type you go for, you need to consider the abrasive flap density, the angle and the spacing of its flaps on the backing plate. Standard density discs are a great choice for heavy-duty applications and fast stock removal. High density flaps are the ideal abrasives for working on curved and uneven surfaces, as well as for finer grit bending and finishing.

When using flap discs, you need to make sure you’re using the machine properly, and that you’re wearing proper protection equipment like safety gloves, jackets, boots and goggles. The safety gloves enable you to get a proper grip of the machine and absorb the vibrations, while the goggles ensure that no harmful objects or dust gets into your eyes. Moreover, make sure there aren’t flammable materials around the place where you work.

The other safety aspect, as briefly aforementioned, is how you use the tool. In order to get the maximum out of it, you need to make sure you’re operating it skillfully. Don’t be callous, as it may negatively impact the task you’re working on, and it may be dangerous. Pay attention to the user manual and know the working pressure and angle. Excessive pressure may result in overheating, while not enough pressure may result in an undesired finish. The best way to tackle this is to apply more pressure initially, then gradually reduce it to a more comfortable level.